If you’re wondering how many different types of CNC machines there are, you’ve come to the right place. This article will explain the difference between 3-axis, three-plus-one axis, four-axis, and 5-axis CNC machines. Once you’ve got the basics down, you’ll be ready to start shopping for your new machine.

3. +1 axis

A 3+1 axis CNC machine is a versatile tool for manufacturers who need to mill parts with a high degree of precision. A 3+1 axis machine is an alternative to a 5-axis machine. This machine combines three axes for machining parts in various sizes and shapes, but it also features additional features such as automatic dimensional alignment. It is also capable of turning parts of various shapes and sizes, making it a versatile tool for any business.

2. axis

CNC machines can be classified into two major types: 3 axis and 5-axis. Three-axis machines require only one workstation and are useful for cutting large parts, such as a table. They also reduce part movement, which helps reduce creation time and improve precision. In addition, three-axis CNC machines can cut slots, which are useful for making furniture pieces and accommodating other parts. When done correctly, slotted parts can hold other parts in place.

3. axis

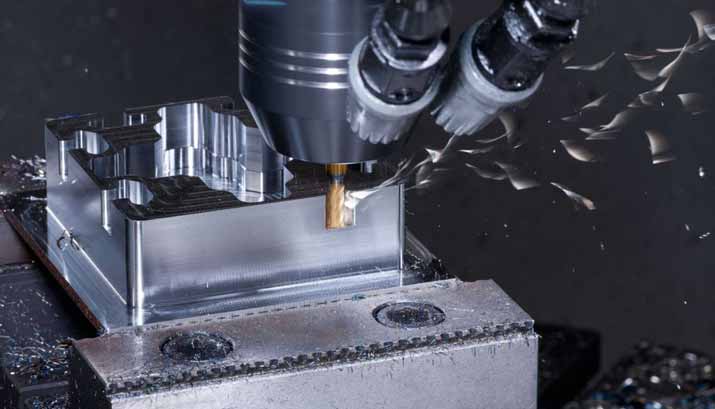

There are two primary types of CNC machines – milling and routers. CNC milling machines are large and expensive, used for hard metal machining, while routers are more affordable and used for softer materials. Okuma is a popular large CNC milling machine manufacturer. While milling machines have more features, they are less accurate than routers and are also less expensive. This article will outline the key differences between milling and router CNC machines, Sneak a peek at this website.

4. axis

If you’re thinking about buying a CNC machine but aren’t sure what type you need, you may wonder: “How many types of CNC machines have four axes?” The answer is surprisingly complicated. There are many different types of CNC machines, but they all have the same basic purpose – to produce parts. In this article, you’ll learn about four popular types of CNC machines, and how they differ from each other.

5. axis

Generally, five-axis machines have two extra axes than their traditional counterpart. They are capable of complex movement and rotation, and have the advantage of simultaneous operation. A typical 5-axis machine can process five faces simultaneously. This is important since about 60% of CNC parts require five-sided machining. The benefits of using this machine are numerous, and it is worth the money you’ll spend for a CNC machine with this feature.

6. axis

CNC (Computer Numerical Control) machines are highly versatile and can be customized to manufacture the most complex components. They are also more accurate and reduce manufacturing time by 75%. The main advantage of 6-axis machines is their ability to produce complex shapes, including structural aircraft parts and medical components. Moreover, the machines have a smoother workflow, which makes them useful in large-scale productions.

Conclusion:

A 7-axis CNC machine is one that operates over seven axes, including three translational axes for cutting tool movement, two rotary axes for holding the workpiece, and one additional axial cylinder for rotation of the tool head. The machine expands upon the multiaxis paradigm, providing the same or even more functionality than its predecessors. A 7-axis machine can complete all of the tasks of its predecessors, as well as perform even more.